- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

Ever wondered what makes industrial mixers tick? The key to high-quality, consistent products often lies in the flow of the liquids inside the mixer. Understanding Reynolds number is essential for optimizing this process.

In this article, we'll dive into what Reynolds number is, how it affects the mixing process, and why it's crucial for selecting the right industrial mixer. By the end, you'll have a better grasp of how this dimensionless number can lead to more efficient mixing and improved results.

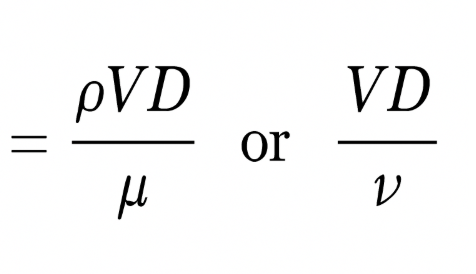

Reynolds number (Re) is a dimensionless value used in fluid mechanics to predict the flow patterns of liquids. It is defined as the ratio of inertial forces to viscous forces in a fluid. This ratio helps predict whether a fluid will exhibit laminar or turbulent flow. The Reynolds number equation is as follows:

Re

Where:

● ρ is the fluid density (kg/m³),

● V is the flow velocity (m/s),

● D is the characteristic length or diameter (m),

● μ is the dynamic viscosity (Pa·s),

● ν is the kinematic viscosity (m²/s).

The Reynolds number helps predict whether the fluid will flow smoothly in laminar layers or erratically in a turbulent manner. This information is crucial in industrial mixing because it determines how fluid behaves within the mixing system, which in turn influences the choice of equipment, such as the type of impeller to use, and the mixing speed required for optimal results.

The concept of Reynolds number was first introduced by George Gabriel Stokes, a professor of mathematics at Cambridge, in the 19th century. However, it was Osborne Reynolds who popularized its use in the 1880s, making it an essential part of fluid dynamics. The Reynolds number was not officially named by Stokes but was named after Reynolds himself in the early 20th century by Arnold Sommerfeld, a German theoretical physicist, who brought more recognition to the concept. Since then, the Reynolds number has become a fundamental concept in the design and optimization of industrial mixing systems and is widely used in fluid mechanics for both engineering and scientific purposes.

Laminar flow is characterized by fluid movement in smooth, orderly layers. Each layer flows smoothly in parallel with the other layers, with minimal disruption between them. In this type of flow, the fluid's velocity remains consistent across the layers, and there is little mixing between them. Laminar flow is ideal for situations where controlled, gentle mixing is required. When the Reynolds number is less than 2,000, the flow remains laminar, making it suitable for low-viscosity fluids like water. In industrial mixers, laminar flow is effective for maintaining uniform fluid movement without creating excessive turbulence or energy consumption. However, this type of flow may not be suitable for larger or more complex systems where rapid and thorough mixing is necessary.

Turbulent flow is chaotic and characterized by irregular fluctuations in the fluid's velocity, resulting in swirling motions, eddies, and vortices. Unlike laminar flow, turbulent flow involves significant interaction between the fluid layers, which enhances mixing and results in a more uniform distribution of the components. For fluids with a Reynolds number greater than 4,000, the flow becomes turbulent, leading to high shear forces and rapid mixing. Turbulent flow is particularly useful in industrial mixing when dealing with high-viscosity fluids or when rapid and efficient mixing is required, such as in the pharmaceutical and chemical industries. The chaotic nature of turbulent flow facilitates more thorough blending of the materials and ensures better heat and mass transfer.

The Reynolds number between 2,000 and 4,000 represents the transitional flow zone. In this range, the flow can fluctuate between laminar and turbulent states depending on other variables, such as the mixing speed, fluid properties, and mixer design. Transitional flow can present challenges in industrial mixing systems, as it may lead to inconsistent mixing results. It is essential to understand the conditions under which transitional flow occurs and adjust the mixing process accordingly to ensure stable and efficient performance.

Flow Type | Reynolds Number Range | Characteristics | Impeller Type |

Laminar Flow | ( Re < 2000 ) | Smooth, orderly flow, minimal disruption between layers | Anchor, Double Helix Impellers |

Turbulent Flow | ( Re > 4000 ) | Chaotic, swirling flow with high shear forces | Axial Flow Hydrofoils |

Transitional Flow | ( 2000 < Re < 4000 ) | Fluid may switch between laminar and turbulent states | Varies based on conditions |

Reynolds number has a profound impact on the design of industrial mixers. The flow regime, whether laminar or turbulent, plays a crucial role in determining the appropriate impeller geometry and size, the speed at which the impeller should rotate, and the overall mixer design. In laminar flow systems, mixers typically use impellers designed for low shear, such as anchor impellers or double helix impellers, which allow the fluid to move in smooth, parallel layers. For turbulent flow systems, high-efficiency axial flow hydrofoils are often used, as they are designed to induce strong shear forces and create significant turbulence for efficient mixing. The type of impeller used is determined by the Reynolds number, ensuring that the mixer operates efficiently and meets the specific requirements of the fluid being mixed.

Reynolds number also directly affects the mixing efficiency of industrial mixers. For low Reynolds numbers (laminar flow), slower mixing speeds and smaller impellers may be sufficient to ensure uniformity and consistency. However, in high Reynolds number systems (turbulent flow), larger impellers and higher mixing speeds are required to achieve effective mixing. Understanding the Reynolds number allows operators to fine-tune their mixing process, optimizing both the energy consumption and mixing performance. By selecting the appropriate impeller and adjusting the mixing speed according to the flow regime, manufacturers can ensure that their mixing systems operate at peak efficiency.

The viscosity of the fluid is another key factor in determining the Reynolds number. Fluids with high viscosity tend to have lower Reynolds numbers and are more likely to exhibit laminar flow. For these fluids, the mixing process must be carefully controlled to prevent inadequate mixing. In such cases, adjusting the impeller design, mixing speed, and other system parameters becomes essential for overcoming the resistance to flow that high-viscosity fluids exhibit. Lower viscosity fluids, on the other hand, tend to flow more freely and are more likely to experience turbulent flow, which is ideal for efficient mixing. Optimizing the mixing process for varying viscosities ensures that the desired mixing results are achieved, regardless of the fluid type.

Calculating the Reynolds number for a specific mixing system involves the following steps:

1. Find Fluid Properties: Obtain the density and viscosity of the fluid at operating conditions. These values can be found in engineering handbooks or online resources.

2. Measure Flow Velocity: Determine the average velocity of the fluid being mixed. This can be calculated based on the flow rate and the size of the mixing vessel.

3. Measure Characteristic Length: For cylindrical vessels, this is the diameter of the vessel; for non-circular shapes, calculate the hydraulic diameter.

4. Apply the Formula: Insert the values into the Reynolds number equation to calculate the flow regime. Based on the result, engineers can determine whether the flow is laminar, transitional, or turbulent.

Step No. | Description | Action Required |

1 | Find Fluid Properties | Obtain fluid density ((ρ)) and viscosity ((μ) or (ν)) |

2 | Measure Flow Velocity | Determine the average velocity ((V)) of the fluid |

3 | Measure Characteristic Length | Calculate the characteristic length ((D)) for the system |

4 | Apply Reynolds Number Formula | Insert values into the formula ( Re = \frac{VD}{ν} ) or ( Re = \frac{ρVD}{μ} ) |

Computational Fluid Dynamics (CFD) simulations are a powerful tool for predicting fluid behavior and calculating the Reynolds number in complex mixing systems. CFD allows engineers to model fluid flow under various operating conditions and optimize design parameters accordingly. By using CFD simulations to predict the flow regime and Reynolds number, manufacturers can improve mixer designs, reduce energy consumption, and ensure consistent product quality. This computational approach is particularly valuable in large-scale industrial mixing systems, where optimizing fluid dynamics can lead to significant improvements in operational efficiency.

In industrial pipelines, the Reynolds number plays a crucial role in determining whether the fluid flow will be laminar or turbulent. This prediction has significant implications for the design of the pipeline, including factors such as pipe size, pumping requirements, and energy consumption. Turbulent flow, which occurs at higher Reynolds numbers, typically results in increased friction and pressure drop, requiring more energy to pump fluids over long distances. By understanding the Reynolds number, engineers can design more efficient pipelines that reduce operational costs and enhance performance.

In chemical reactors, efficient mixing is essential for achieving consistent product quality and maximizing reaction rates. The Reynolds number helps predict how fluids will behave under mixing conditions, allowing engineers to select the appropriate impeller design and mixing speed. For highly viscous fluids, a low Reynolds number system with gentle mixing may be required, while for less viscous fluids, a turbulent flow system with higher shear forces may be necessary. Understanding the Reynolds number in this context helps optimize the reactor design and ensures consistent product output.

Viscosity Range | Reynolds Number Range | Typical Fluid Types | Recommended Mixing Approach |

Low Viscosity | ( Re > 4000 ) | Water, Low-viscosity oils | Use high shear impellers for efficient mixing |

High Viscosity | ( Re < 2000 ) | Syrups, Gels, Creams | Use slow-speed impellers for gentle mixing |

Understanding Reynolds number is essential for optimizing industrial mixing processes. By considering the Reynolds number during mixer design, manufacturers can improve efficiency, reduce energy usage, and enhance product quality. Whether dealing with low or high-viscosity fluids, knowing when flow is laminar or turbulent is key to achieving consistent results. This knowledge helps engineers fine-tune mixing systems, ensuring maximum efficiency and meeting product specifications.

JiangSu KeHeng Petrochemical & Electrical Machinery Co., Ltd offers innovative solutions that enhance mixing processes. Their products provide exceptional value by ensuring efficiency and precision in industrial applications.

A: Reynolds number is a dimensionless quantity used to predict flow regimes in industrial mixing. It helps determine whether the flow is laminar or turbulent, which impacts the mixing efficiency in an Industrial Mixer.

A: Reynolds number influences impeller selection and mixer design. For laminar flow, anchor impellers are used, while turbulent flow systems require high-efficiency impellers like axial flow hydrofoils to optimize mixing.

A: Understanding Reynolds number ensures optimal mixer performance by helping engineers fine-tune the impeller speed and design, reducing energy consumption and improving product quality.

A: If an Industrial Mixer is not achieving the desired mixing results, checking the Reynolds number can help identify if the flow is too turbulent or laminar, allowing adjustments to improve performance.