- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

Customized Industrial Mixers:

Tailored Solutions for Your Needs

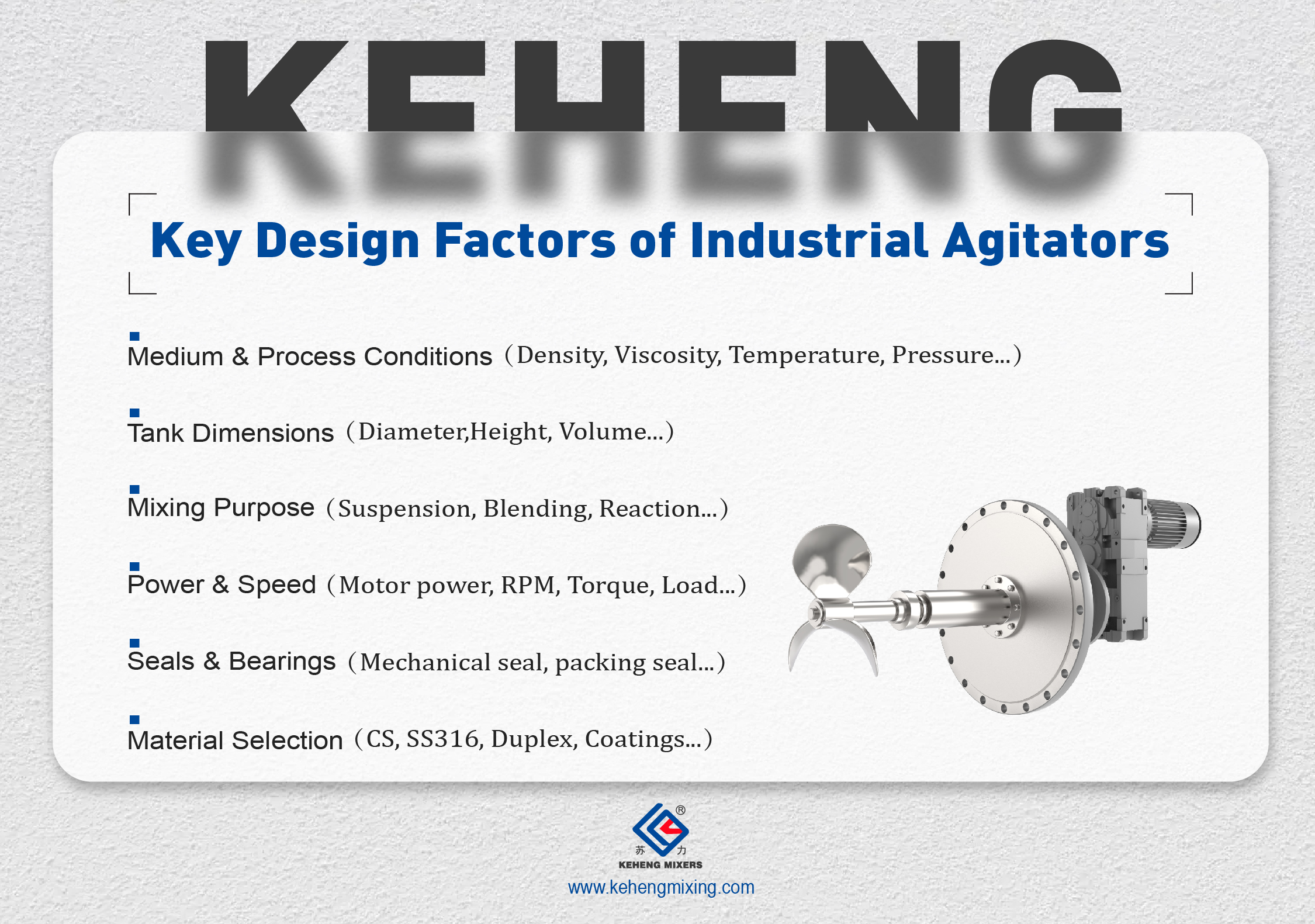

In modern industrial production, every tank, reactor, or mixing vessel has unique operating conditions. The viscosity, density, temperature of the liquid, and required flow pattern, shear rate, and mixing uniformity all directly affect the design of the mixer. Standard mixers often cannot meet complex process requirements, making custom industrial mixers essential for improving production efficiency, ensuring mixing quality, and safe operation.

Ⅰ. Process Parameters Drive Mixer Design

Custom mixers are designed based on process parameters. Mixer type, impeller design, speed, power, and transmission method (belt-driven or direct-driven) are optimized according to the liquid properties and mixing objectives.

For example:

High-viscosity liquids, such as asphalt or adhesives, require side entry mixers with large-diameter impellers for proper circulation and uniform blending.

Low-viscosity liquids or chemical reaction fluids, such as water treatment solutions, benefit from top entry mixers for uniform mixing and fast reactions.

Ⅱ. On-site Conditions Affect Equipment Selection

Beyond process parameters, site conditions also impact mixer selection. Tank size, installation space, piping layout, and maintenance accessibility must all be considered. Custom mixers ensure the equipment fits the site perfectly, avoiding installation and operational challenges.

Ⅲ. Flexible Adjustments and Special Functions Improve Mixing Efficiency

Modern custom mixers offer angle adjustment, impeller replacement, variable speed control, and other features.

For example, belt-driven variable-angle side entry mixers can rotate up to 30°, effectively preventing sediment buildup and improving overall tank mixing efficiency. This is especially suitable for industries like oil, chemical, and water treatment.

Ⅳ. Value of Custom Industrial Mixers

Tailor-made mixers enhance mixing efficiency, extend equipment life, reduce energy consumption, and lower maintenance costs. Custom solutions also help companies meet higher safety and environmental standards, enabling sustainable production and efficient operations.

Ⅴ. KEHENG’s Custom Mixer Advantage

At KEHENG, we design and manufacture mixers based on each client’s specific requirements and on-site conditions. Whether for liquid mixing, tank mixing, chemical reactions, pulp and paper, or wastewater treatment, each mixer undergoes rigorous engineering design, manufacturing, and performance testing to ensure high efficiency, reliability, and long-term operation.

Ⅵ . Customization Process

•Consultation and Assessment

•Design and Engineering

•Prototyping and Testing

•Production and Delivery

Conclusion

Customized industrial mixers are essential for achieving optimal performance in various applications. By focusing on the unique needs of each client, we ensure that our mixers provide effective solutions that enhance mixing processes.

From initial consultation to final delivery, our rigorous customization process guarantees that manufacturers receive equipment tailored to their specific challenges, ultimately leading to improved product quality, greater operational efficiency, and enhanced competitiveness in the market.

55kW Variable Angle Side Entry Mixer for Oil Storage Tank Project in Thailand

55kW Variable Angle Side Entry Mixer for Oil Storage Tank Project in Thailand

Sustainable Mixing: How To Reduce Energy & Waste in Industrial Agitation

Efficient Bitumen Mixing: Choosing The Right Agitator for Asphalt Production

How To Optimize Mining Wastewater Treatment with Industrial Mixers

Customized Industrial Mixers: Tailored Solutions for Your Needs

Solids Suspension And How It Affects Agitator Design for Your Process

How Agitators Support the Clarification Process in Water Treatment