- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

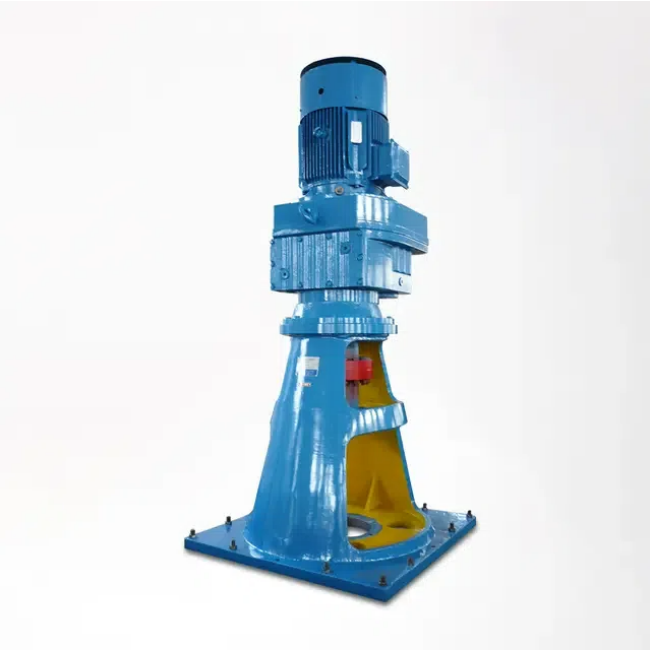

Investing in a high-performance Top Entry Mixer can transform your production process, delivering faster mixing, lower energy consumption, and reduced downtime. Facilities that upgrade to KEHENG’s top-mounted designs frequently experience measurable improvements in productivity, product consistency, and operational cost savings. Beyond efficiency, these mixers provide operational flexibility, safety, and compliance advantages that are increasingly essential in modern manufacturing. Here are seven concrete reasons why a Top Entry Mixer represents a smart investment for industrial operations seeking efficiency and reliability.

One of the most compelling reasons to invest in a Top Entry Mixer is its ability to provide superior mixing efficiency and consistent product quality. The design of top-mounted mixers enables axial-flow impellers to circulate materials effectively from the top, ensuring that every batch achieves homogeneity faster than conventional side-entry or bottom-mounted units. This consistent performance reduces rework and minimizes scrap, directly impacting profitability.

To validate the efficiency gains, facilities can monitor key performance indicators such as mixing time, coefficient of variation (CV), and scrap rates. For example, a properly selected impeller can reduce mixing time by up to 30% while maintaining uniformity across the batch. Facilities can also track the reduction of dead zones in tanks, ensuring that viscous liquids or suspensions are fully integrated. KEHENG’s Top Entry Mixers are engineered to provide predictable scale-up behavior, making pilot test data highly reliable for full-scale production. Continuous monitoring allows operators to optimize impeller speed and positioning for different products, enhancing both efficiency and product quality.

Energy efficiency is another significant advantage of Top Entry Mixers. By selecting the appropriate impeller type, axial-flow mixers can dramatically reduce power consumption compared to inefficient alternatives. Many vendors, including KEHENG, provide performance and power curves to help facilities estimate expected energy savings.

Energy costs represent a major portion of operational expenses, especially in high-volume processes. Top-mounted designs can cut energy use by optimizing fluid flow and minimizing dead zones, making the mixer not only more efficient but also more sustainable. Beyond electricity savings, reduced energy consumption also decreases heat generation, contributing to improved working conditions in enclosed tanks. When evaluating CAPEX, the potential reduction in OPEX from lower energy bills should be factored into the overall ROI. For facilities with multiple tanks, the compounded energy savings can justify the upfront investment in a top-mounted system within a few production cycles.

Top Entry Mixers are highly versatile, capable of handling a broad range of processes and product viscosities. From low-viscosity blending to high-viscosity kneading, KEHENG’s mixers can accommodate modular impeller sets designed for gas dispersion, solids suspension, or heat transfer tasks. This flexibility reduces the need for multiple specialized mixers and simplifies inventory management.

Industries such as chemical processing, food and beverage, pharmaceuticals, wastewater treatment, metallurgy, construction, and oil & gas all benefit from the adaptability of top-mounted designs. For instance, in chemical processing, a single Top Entry Mixer can handle both liquid-liquid emulsions and solid suspensions, reducing the number of different machines needed. In food production, these mixers can simultaneously integrate flavors and maintain product integrity without damaging delicate ingredients. The ability to adjust impeller types and configurations ensures that one mixer can meet the demands of various products, reducing capital expenditure and improving operational flexibility.

Scaling up a process from pilot to full production can be challenging, but top-mounted mixers simplify this transition. By leveraging non-dimensional numbers such as Reynolds and power numbers, along with vendor-provided scale-up data, engineers can predict how the mixer will perform in larger tanks without costly trial and error.

Facilities should review vendor scale-up charts and, if necessary, conduct pilot tests to validate mixing times and uniformity. KEHENG provides detailed guidelines for full-scale predictions, ensuring that the same level of product quality achieved in small-scale testing is reliably reproduced in production-scale operations. For complex products, such as those with variable viscosities or temperature-sensitive ingredients, additional simulation using computational fluid dynamics (CFD) can help optimize impeller type and positioning before installation. This predictive approach not only reduces startup issues but also ensures consistent batch-to-batch quality from the outset.

Maintenance accessibility is another critical factor when considering industrial mixers. Top-mounted designs allow straightforward access to gearboxes, motors, and impellers, reducing downtime during routine service or part replacement. KEHENG’s Top Entry Mixers incorporate user-friendly designs for seal replacement and spare parts management, simplifying maintenance planning and avoiding prolonged production stoppages.

Operators should inspect the mixer’s gearbox, motor mounting, and seal arrangements regularly. Top-mounted configurations make it easier to perform these inspections without dismantling the entire system, which contributes to higher uptime and more predictable maintenance schedules. Additionally, KEHENG’s mixers are designed with modular components that can be swapped quickly, minimizing production interruptions. Staff training on routine maintenance further ensures that mixers operate reliably over years of continuous use.

For industries where hygiene and regulatory compliance are critical, Top Entry Mixers offer enhanced sanitary options. Food, beverage, and pharmaceutical facilities require CIP (clean-in-place) and COP (clean-out-of-place) readiness, smooth surface finishes, and appropriate seal/booting materials to prevent contamination. KEHENG’s sanitary top-mounted mixers are designed to meet these stringent standards while delivering consistent performance.

When selecting a mixer for sensitive applications, check the surface finish, CIP/COP compatibility, and available seal options. KEHENG’s mixers provide these features, ensuring that operations meet industry regulations while maintaining high efficiency and reliability. Moreover, these sanitary designs reduce cleaning times, minimize the risk of cross-contamination, and support faster product changeovers—critical for food and pharma manufacturers managing multiple product lines.

While CAPEX is an important consideration, the total cost of ownership (TCO) for a Top Entry Mixer often proves even more compelling. Reduced batch time, increased throughput, lower energy use, and simplified maintenance contribute to tangible savings over the life of the equipment.

A simple ROI calculation can help justify the investment:

Time saved per batch × increased throughput = production gain

Energy savings = OPEX reduction

Maintenance hours avoided = labor and downtime reduction

By quantifying these savings, plant managers and procurement teams can demonstrate clear financial benefits to stakeholders. KEHENG provides supporting data and operational benchmarks to assist with precise ROI calculations, making it easier to compare potential returns from different mixer options and justify top-mounted designs as long-term investments.

Investing in a KEHENG Top Entry Mixer allows facilities to achieve faster mixing, consistent product quality, energy savings, and reduced downtime while maintaining compliance with industry standards. With versatile applications, predictable scale-up, and clear TCO advantages, top-mounted mixers are an investment that delivers measurable returns across multiple sectors. If a Top Entry Mixer fits your process needs, contact KEHENG today to arrange a process evaluation, request a mixing trial, or download our ROI template for informed decision-making and optimized production results.