- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Background introduction:

In April 2024, KEHENG participated in the IE Expo China in Shanghai, which is one of the largest and most influential exhibitions in the environmental protection industry. During the exhibition, we were fortunate to meet a customer from Cyprus. The customer put forward his demand at the exhibition site, requiring us to provide suitable agitators to install on their sludge tank. Subsequently, the customer provided the specific size of sludge tank, with a diameter of 6m and a height of 8m, and the density of the sludge slurry is 900-1200kg/m³. In the face of customer need, we inmediately activared the emergency response mechanism.

Rapid response and develop the proposal:

In order to ensure that customers can get the required solutions as soon as possible, we immediately transferred the customer's requirements to our technical department, and arrange professionals to design and select model. The technical team quickly analyzed the data, combined with the sludge tank size and media information provided by the customer, and designed a set of efficient agitator solutions. The next day, we sent proposal to the client for review. This quick response not only demonstrates our professionalism, but also deepens our customers' trust in us. In the following time, we followed up several times, to ensure that our solution can fully meet the needs of customers.

After careful review, the client emailed us in mid-May. He expressed general satisfaction with our proposal and requested us to provide a detailed quotation. At the same time, the customer clearly proposed the need for CE certification and EC Declaration of conformity. Then we further confirmed with the customer the number of mixers required and discussed the terms of the offer, to ensure that all details met the customer’s commercial needs.

Professional advice:

In the process of solution design, we adhere to the principle of "customer-centric", focusing on providing customers with the best solution. According to the customer's requirements, we chose 316L stainless steel as the material for the mixing shaft and blades. It can ensure the corrosion resistance and durability of the equipment in harsh environments. When reviewing the quotation, our responsible person put forward an optimization proposal - carbon steel lining and anti-corrosion treatment of the blades can be used, which can effectively reduce costs under the premise of ensuring performance. As a result, we provide our customers with two feasible quotations to choose from. After consideration, the customer finally decided to choose 316L stainless steel with more long-term reliability. This fully reflects the customer's high standard of quality requirements.

Modify solution:

About a week later, the customer asked to modify the solution. They provided a more accurate tank size: 5.4m in diameter and 8.6m in height, and requested installation instructions for the mixer.

At the same time, the customer also put forward a new demand - want to add a frequency converter in the equipment, in order to be able to control the mixing speed. This requirement means that we need to adapt the solution. We immediately communicated with the technical team, quickly made corresponding adjustments, adopted a inverter motor, and advised the customer to install the control cabinet on site to achieve frequency control. This flexibility makes our customers more satisfied with our services. This modification plan was finally confirmed after customer review.

Order confirmed:

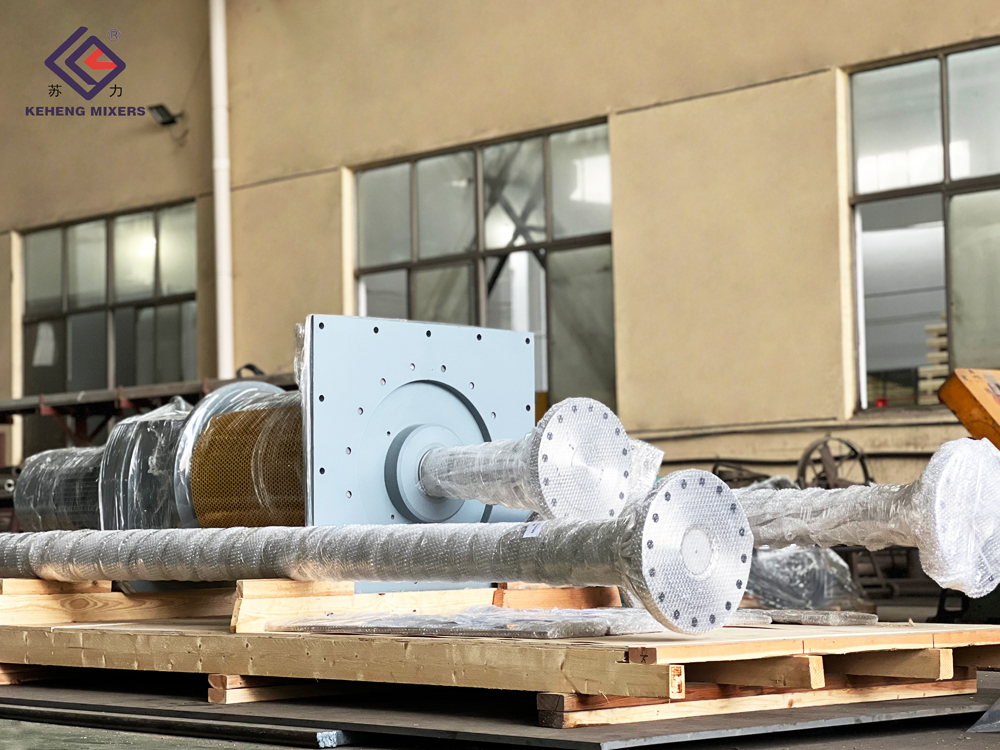

With our professional services and technical support, the customer finally confirmed the order of two vertical mixers and arranged the deposit payment. This marks the beginning of the substantive phase of our cooperation, and we are very proud to be an important partner of our customers.

So far, the mixers have been delivered to our customer. We are confident in the excellent performance of these agitators, which have been rigorously tested for efficient and reliable mixing capabilities. They are expected to play an excellent performance in the customer's project site, provide a solid guarantee for the customer's production process, and make an important contribution to the success of the project. We sincerely hope that this batch of mixers can help customers achieve remarkable results in future applications and lay a more solid foundation for cooperation between the two sides.

content is empty!